Popular Highlights

When only a watchmaker will do

Restoration of Omega Jump Seconds Clock

|

Restoration of a Rare RAF Time of Trip Clock

Swiss Trained, Omega Recognized Provider |

|

|||

|

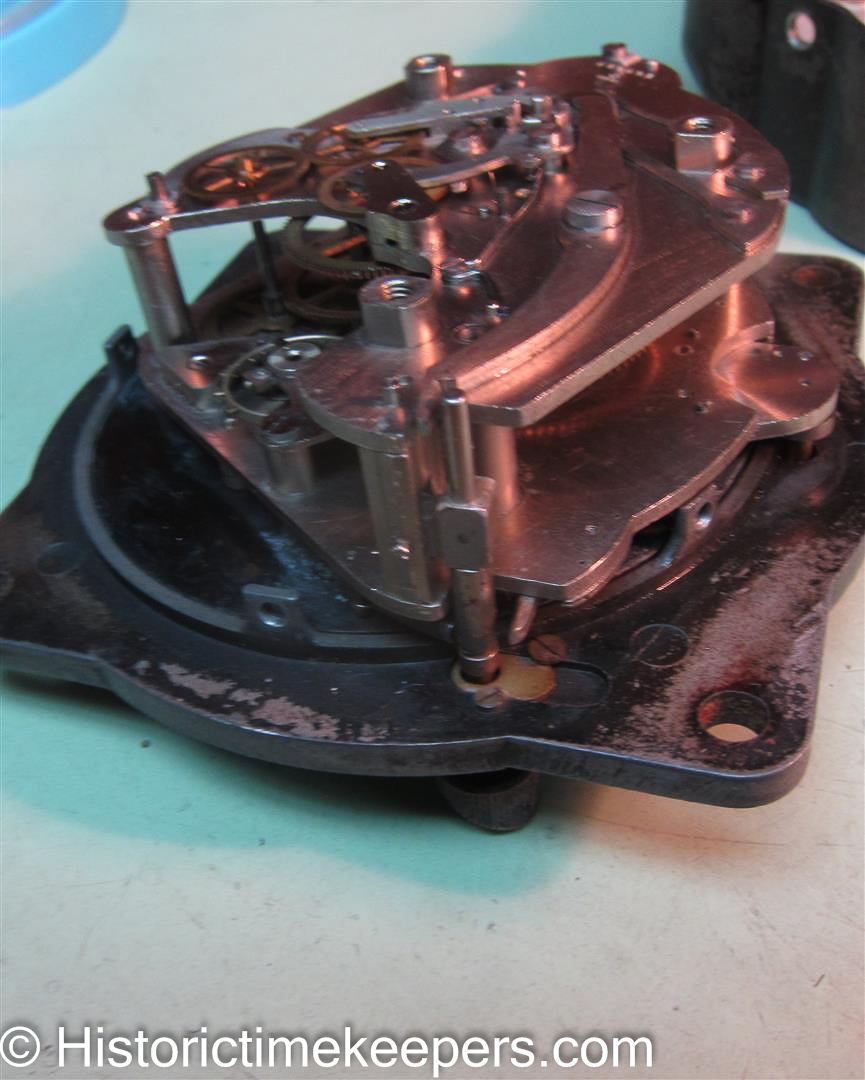

Rare and unidentified 1937 RAF issued Swiss Time of Trip Clock This is a clock I had never before seen. It is fully marked for WWII Air Ministry and is of Swiss manufacture. Until I could get it fully disassembled, I at first thought it was a British Copy made under duress. It is NOT a Lecoultre and it is of lesser quality in design and execution. Kind of reminds me of Swiza. But the only mark is "Swiss" with absolutely no maker's ID. Interesting. The first problem was to uncase the piece. The TOT knob on the left is not the typical pusher type, but you push down vertically. The screw for that knob was badly rusted and the head was deformed. There was no room to mount the piece in a vise and mill the screw out. Obviously, the knob and the case had to be preserved intact.

In consultation with owner, it was decided that since I could duplicate the TOT operating arbor I should part the arbor just below the knob. I then dissolved the remaining steel in the knob, preserving it. After the movt was uncased, an it was revealed that inexperienced workman had destroyed the balance fork. This kind of thing happens with people who have no idea of the effort required to make something. It was not a major issue when parts were available; but now that parts for vintage pieces no longer exist and parts for more modern pieces are becoming depleted, such damage must be avoided.

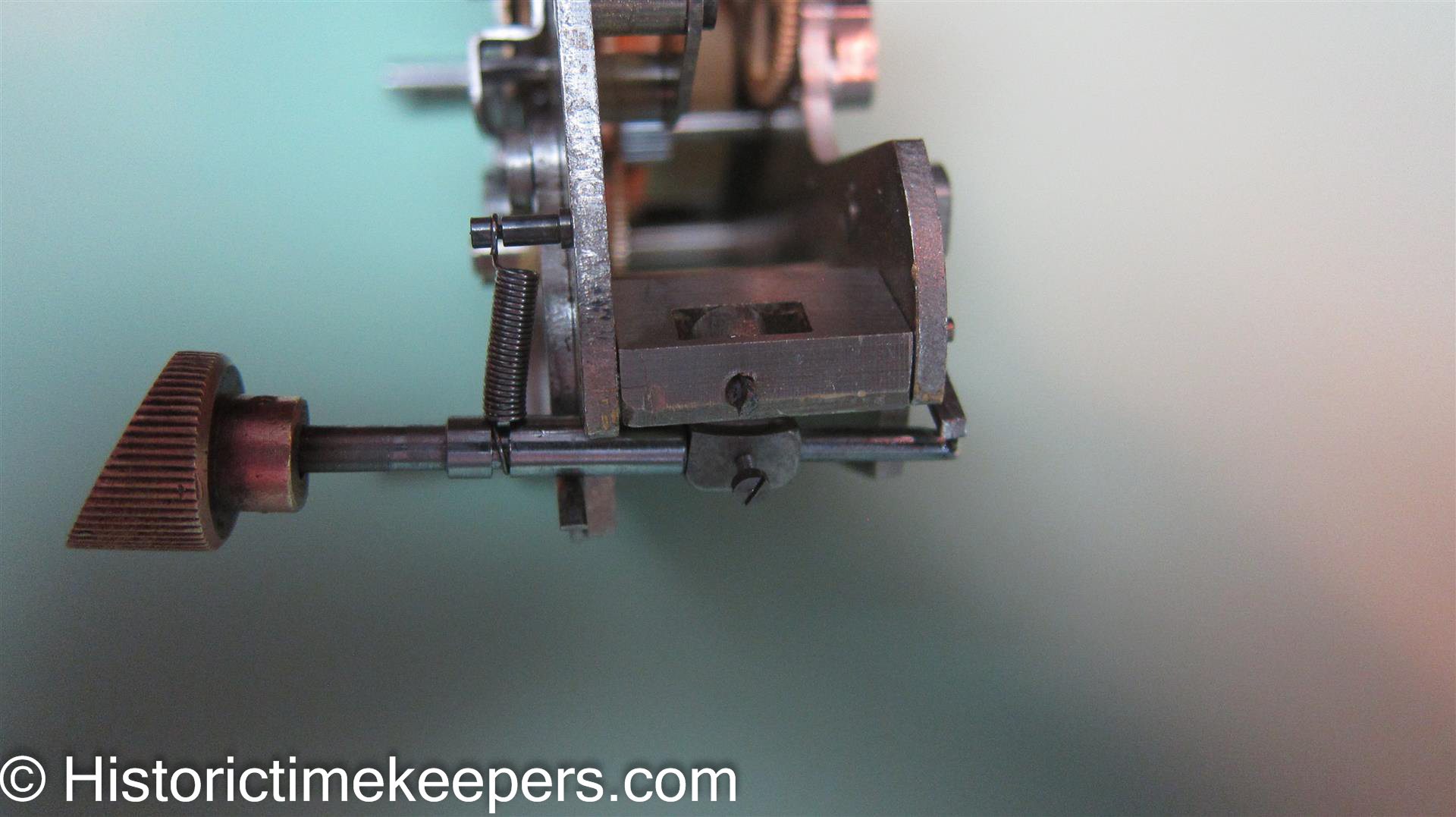

The pallet fork safety horn is crushed by poor handling and using the Nikon optical comparator to select a replacement candidate While I have made most watch parts I have not occasion to make a pallet fork (thankfully). And if it was required for this piece, the cost would have been a show stopper. Fortunately, I know something about how the Swiss cartels worked and knew that there is a limited selection of standardized escapement sets that were purchased from one supplier. I have been in business for almost 40 years and years ago started purchasing material such as jewels, staffs and escapement parts in bulk. So using the optical comparator I was able to select a proper candidate even though I had to enlarge the slots to take the original pallet jewels. Another issue became apparent after the work was "completed". Testing revealed a serious fault in the TOT (time of trip) function. In most TOT clocks, the center seconds chrono (elapsed time) is independent of the 12 hour TOT function. As a cost savings, the operating lever I had to make operated both functions as one unit. Close inspection revealed that the beak of the center seconds intermediate wheel lever had been shortened. This meant that the intermediate wheel could never lift off the center seconds runner even when the TOT was paused or reset. Of course, this stops the clock. This was apparently done by someone who did not know the theory of chronographs and thought they could make the center seconds run continuously. If you have a better theory let me know.

We would have preferred for me to make the upper block of the lever, but cost was becoming an issue. There was spare height on the column wheel. I made a patch for 1/4 the cost of a new lever that fit over the shortened beak. If an owner in the future choose, this can be used as the template for making the new lever upper block. But since it now functions, that of course is unlikely.

The machined and hardened "patch" pinned to the intermediate wheel lever

The repaired intermediate wheel lever installed in the timepiece The new operating arbor was manufactured and installed. Rather than use the cross pin to keep the knob oriented (an apparent cost savings) I tapped the hole in the block and used a grub screw. this will avoid a situation in the future similar to what I encountered.

|

||||